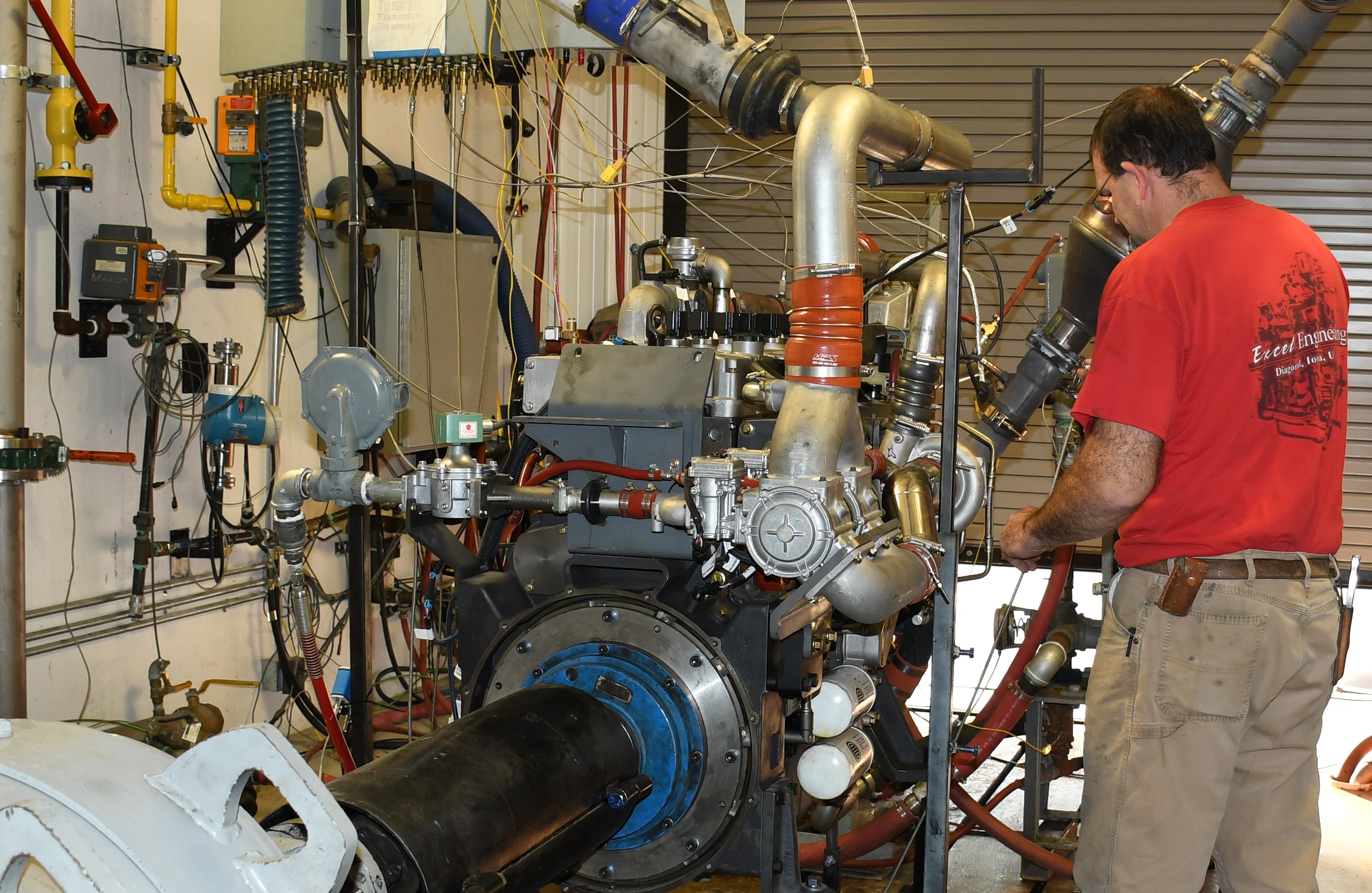

Durability and Endurance Testing

Our engine durability test cells are simple, reliable, and cost effective. Offering 24/7 operation, we average 140+ run hours per week on our customers projects. Excel’s automation and controls allow flexibility and reduce the need for operator’s, savings our customers money. We can program any customer specific durability test cycles. Safety monitoring with automatic alarms and shutdowns protect your investment. IP cameras allow access around the clock. Our technicians can perform all your service and maintenance requirements with full documentation. We have engine oil analysis available.

- Test Cycles

- Industry standard cycles

- Proprietary cycles

- Custom designed cycles

- OEM specific tests

- Emissions deterioration factors

- Complete engine validation

- Component durability

- Power checks

- Blowby monitoring

- Compression and leak down

- Fuel and lubricant evaluations

- Octane requirement

- Knock evaluations

- Oil consumption evaluations

- Failure analysis

- Testing Capabilities:

- Transient capable Eddy-current dynamometers

- Combustion air control (temp and humidity)

- Exhaust back pressure control

- Heated and Chilled fluids

- Automated data acquisition and control

- OEM diagnostic equipment

- Road simulation cycles

- Catalyst ageing

- Vehicle drive cycle simulation

- Thermal shock

- Manifold cracking